Why Is the Gate Valve Still the Preferred Choice for Controlling Fluid Flow in Modern Systems?

2025-02-21

In the world of industrial piping systems, valves play a critical role in controlling the flow of liquids and gases. Among the many types of valves available, the gate valve stands out as one of the most reliable and commonly used. But why has the gate valve maintained its position as the preferred choice for fluid flow control in so many industries, even in today’s advanced technological landscape? And what is it about this simple yet highly effective valve that continues to make it an essential component in modern infrastructure?

What Is a Gate Valve?

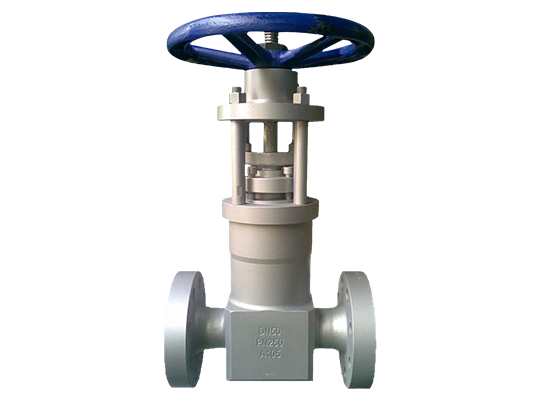

A gate valve is a linear motion valve used to control the flow of liquids and gases through a pipeline. Its primary function is to completely stop or allow the passage of fluid by raising or lowering a gate (or wedge) within the valve body. When the valve is in the open position, the gate is lifted from the flow path, allowing for unrestricted flow. When closed, the gate moves into the flow path to completely block the fluid.

Gate valves are typically used in applications where the valve either needs to be fully open or fully closed, as they are not designed for throttling or regulating flow. They are often found in large pipelines, waterworks, chemical processing, oil and gas, and many other sectors.

Why Is the Gate Valve Still So Popular?

1. Full Flow and Minimal Resistance

One of the biggest advantages of a gate valve is its ability to provide a full, unrestricted flow when open. Unlike other valve types, such as globe valves, which can create resistance even when fully open, gate valves offer little to no obstruction to the fluid’s path. This means that when the valve is open, fluid flows freely, and there is minimal pressure drop across the valve.

This is especially important in systems where high flow rates are required or where maintaining optimal pressure is crucial. The design of the gate valve ensures that it causes minimal interference with the flow of liquid or gas, making it an excellent choice for pipelines carrying water, oil, natural gas, and other essential fluids.

2. Durability and Longevity

Gate valves are designed to be highly durable, capable of withstanding tough operating conditions in a variety of industries. They are typically made from corrosion-resistant materials such as stainless steel, cast iron, or brass, which ensures they can handle the pressure and temperature extremes present in many industrial environments.

These valves are built to last for years, making them a long-term solution for fluid flow control. Their sturdy construction means that they are less prone to damage or wear compared to other types of valves, particularly when exposed to harsh chemicals or extreme conditions.

3. Simple Design and Ease of Maintenance

The gate valve’s simple design makes it easy to operate and maintain. With fewer moving parts than more complex valves, such as control valves, gate valves are less likely to malfunction. The mechanism is straightforward, usually consisting of a stem, gate, and bonnet, which means there are fewer opportunities for failure.

Moreover, gate valves are relatively easy to repair or replace, making them cost-effective over their lifespan. In the rare event that maintenance is needed, the valve’s design allows technicians to quickly assess and address issues, reducing downtime and keeping operations running smoothly.

4. Cost-Effective

When it comes to cost-effectiveness, gate valves are typically more affordable than other types of valves with more complex mechanisms, such as ball valves or globe valves. This makes gate valves an excellent choice for applications where the valve needs to perform a simple on/off function without the need for intricate flow regulation or throttling.

In addition, their durability means that gate valves often require fewer replacements over time, providing excellent value for money. This is especially beneficial in large-scale systems or those where valves need to be installed in multiple locations.

5. Versatility Across Industries

Gate valves are incredibly versatile and can be used across a wide range of industries and applications. Some of the most common industries that rely on gate valves include:

Water and Wastewater Treatment: Gate valves are widely used in municipal water supply systems and wastewater treatment plants to control the flow of water.

Oil and Gas: In oil and gas pipelines, gate valves are used to isolate sections of the pipeline for maintenance or to stop the flow of oil or gas in emergencies.

Chemical Processing: Gate valves are often used in chemical plants to control the flow of corrosive or hazardous liquids and gases.

Power Generation: Power plants rely on gate valves to control the flow of steam and water in the boiler systems.

Mining and Agriculture: Gate valves are essential for regulating water flow in irrigation systems or in mining operations that require large amounts of fluid transport.

Their adaptability and reliability make them an essential component in virtually every industrial sector.

6. Good Sealing Capabilities

Gate valves are designed to provide an effective seal when closed, preventing any leakage of the fluid being controlled. The gate is typically made of metal and fits snugly into the valve body, ensuring a tight seal that minimizes the chances of leakage. This is particularly important in industries dealing with pressurized liquids or gases, where leaks can result in safety hazards or costly product loss.

The sealing capability of gate valves is one of the main reasons they are chosen for high-pressure and high-temperature applications. Whether used in natural gas pipelines or chemical processing plants, gate valves ensure that the flow is safely and securely shut off when needed.

When Should You Use a Gate Valve?

Gate valves are typically used when a system requires either full flow or complete closure, but not for regulating or throttling the flow of fluid. Some specific use cases include:

Isolation of sections of a pipeline: Gate valves are ideal for isolating sections of a pipeline for maintenance or repair, as they provide a clear, full opening when open and a complete shutoff when closed.

Systems requiring high flow rates: In applications where flow needs to be as unrestricted as possible, gate valves are the preferred choice due to their ability to provide a full, unobstructed path for fluids.

High-pressure systems: Due to their durable construction and effective sealing capabilities, gate valves are often used in high-pressure systems, such as those found in oil and gas pipelines.

Conclusion

Gate valves have been around for a long time, and their continued popularity in modern systems is no accident. With their reliable, simple design, cost-effectiveness, and versatility, they have proven themselves to be essential components in fluid flow control across many industries. From their ability to provide full flow with minimal resistance to their excellent sealing capabilities, gate valves remain the preferred choice for many engineers and industrial operators.

So, why is the gate valve still the preferred choice for controlling fluid flow in modern systems? It’s clear that their combination of durability, affordability, and reliability ensures they will continue to play a pivotal role in fluid control for years to come.