What Is a DIN Hydraulic Adapter and Why Is It Essential in Hydraulic Systems?

2024-11-18

In the world of hydraulic systems, precision and reliability are paramount. To ensure smooth operation and compatibility between various components, the use of DIN hydraulic adapters has become a standard practice. But what exactly is a DIN hydraulic adapter, and why is it so crucial in maintaining the efficiency and safety of hydraulic systems? Let's dive deeper into understanding this important component and its role in industrial applications.

What Is a DIN Hydraulic Adapter?

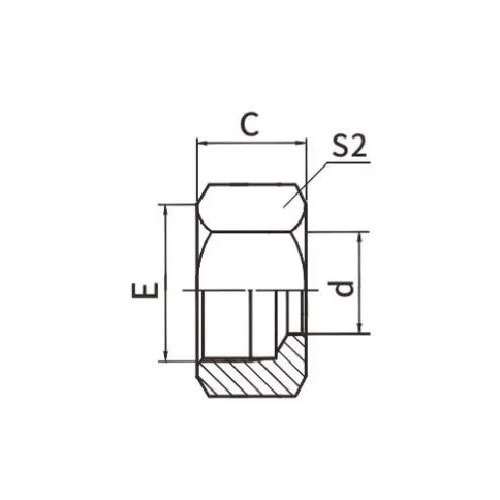

A DIN hydraulic adapter is a fitting that allows two hydraulic components, such as hoses, tubes, or valves, to connect seamlessly. The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which developed a set of standards for hydraulic systems. These adapters are designed to meet these specific DIN standards, ensuring that the components they connect are compatible and can function together without issues.

DIN hydraulic adapters come in various types, including straight, elbow, tee, and reducer designs, and they are used to join components with different thread types, sizes, or pressure ratings. The goal of these adapters is to provide a secure, leak-proof connection between parts, which is essential in high-pressure hydraulic systems where any loss of fluid can lead to inefficiencies or hazardous situations.

Why Are DIN Hydraulic Adapters So Important?

1. Ensuring Compatibility Between Components

Hydraulic systems consist of numerous components, each with specific connection types, sizes, and pressure ratings. DIN hydraulic adapters allow these components, even if they come from different manufacturers, to connect and work together. This standardization simplifies the process of assembling and maintaining hydraulic systems, ensuring that parts are compatible and can operate as intended.

2. Providing Leak-Proof Connections

In hydraulic systems, leaks can be costly and dangerous. They can lead to equipment failure, environmental damage, and even pose safety hazards. DIN hydraulic adapters are designed to create tight, secure seals that prevent fluid from leaking at connection points. This leak-proof quality ensures the system maintains pressure and operates efficiently.

3. Enhancing the Durability of Hydraulic Systems

Hydraulic systems often operate under high pressure, and the components within them are subject to significant wear and tear. DIN hydraulic adapters are typically made from robust materials such as steel, stainless steel, or brass, ensuring they can withstand the high pressures and harsh environments common in industrial settings. The durability of these adapters helps prolong the life of the entire hydraulic system, reducing the need for frequent repairs or replacements.

4. Flexibility and Customization

Because DIN hydraulic adapters are available in a wide range of configurations and sizes, they offer flexibility in design and application. Whether you're working with large machinery, construction equipment, or manufacturing systems, there's a DIN hydraulic adapter that can be customized to meet the specific requirements of your hydraulic system. This adaptability makes it easier to design, modify, and repair hydraulic systems as needed.

5. Simplifying Maintenance and Repairs

Over time, hydraulic systems require maintenance and occasional repairs. DIN hydraulic adapters make these tasks more straightforward by allowing easy disconnection and reconnection of parts. Instead of replacing entire components, operators can use adapters to replace or repair individual sections of the system, saving time and money in the process.

Types of DIN Hydraulic Adapters

DIN hydraulic adapters come in several types to suit different applications. Some common types include:

- DIN 2353 (24° Cone): This is one of the most widely used DIN standards for hydraulic adapters. It features a 24° conical sealing surface that provides a tight and secure seal. Commonly used in high-pressure systems, these adapters offer excellent leak resistance.

- DIN 3852: These adapters are designed for use in hydraulic systems where higher pressures are involved. They feature a flat seal and are known for their reliability and durability.

- DIN 20026: These adapters are often used in applications requiring threaded connections, such as industrial machinery and construction equipment.

- DIN 3861: These are often used in lower-pressure applications or where ease of connection is important. They typically feature a threaded or flanged connection.

Applications of DIN Hydraulic Adapters

DIN hydraulic adapters are used in a variety of industries and applications, including:

- Construction: Heavy machinery, such as excavators, cranes, and bulldozers, all rely on hydraulic systems for power and movement. DIN adapters help ensure that the hydraulic hoses and valves are securely connected and function properly.

- Agriculture: Hydraulic systems are essential in agricultural equipment like tractors, harvesters, and irrigation systems. DIN hydraulic adapters provide the necessary connections for these systems to function efficiently.

- Manufacturing: In factories, hydraulic systems are used in machines that require precise power, such as presses, robots, and conveyor systems. The use of DIN hydraulic adapters ensures that these machines maintain optimal performance.

- Automotive: Many automotive manufacturing processes involve hydraulics, and DIN adapters are used in the production lines, as well as in the repair and maintenance of vehicles.

- Marine: In marine environments, where equipment is often exposed to harsh conditions, DIN hydraulic adapters offer the reliability and durability required to prevent leaks and ensure safe operation.

Choosing the Right DIN Hydraulic Adapter

When selecting a DIN hydraulic adapter for your system, there are a few key factors to consider:

- Pressure Rating: Ensure the adapter can handle the maximum pressure your system will generate to prevent failure.

- Material: Choose an adapter made from corrosion-resistant materials if the system will be exposed to moisture, chemicals, or extreme temperatures.

- Size and Thread Type: Make sure the adapter matches the size and thread type of your system’s components.

- Seal Type: Different applications may require different sealing methods, such as O-rings, seals, or flat seals, depending on the operating conditions.

Conclusion

The DIN hydraulic adapter is a fundamental component in modern hydraulic systems, providing a reliable and efficient means of connecting different components. By ensuring compatibility, preventing leaks, and enhancing durability, these adapters play a crucial role in maintaining the performance and longevity of hydraulic systems. Whether you're in construction, agriculture, or manufacturing, DIN hydraulic adapters are essential tools for ensuring that your equipment operates safely and efficiently.

Do you use DIN hydraulic adapters in your systems? What has been your experience with their performance and reliability? Let us know in the comments!