Understanding Battery PCM/BMS/PCB: Key Components for Safe and Efficient Battery Management

2024-08-10

In the realm of battery technology, ensuring the safety, efficiency, and longevity of batteries is critical. Battery Protection Circuit Modules (PCM), Battery Management Systems (BMS), and Printed Circuit Boards (PCB) play crucial roles in achieving these goals. This blog explores the functions, benefits, and applications of these components, shedding light on their importance in modern battery systems.

What Are Battery PCM, BMS, and PCB?

Battery PCM (Protection Circuit Module): PCM is a crucial component designed to protect batteries from damage caused by overcharging, over-discharging, and short circuits. It ensures that the battery operates within safe limits, preventing potential hazards and extending battery life.

Battery Management System (BMS): A BMS is a sophisticated electronic system that monitors and manages the performance of a battery pack. It provides comprehensive control and protection, ensuring optimal battery operation, balancing cells, and communicating with external systems.

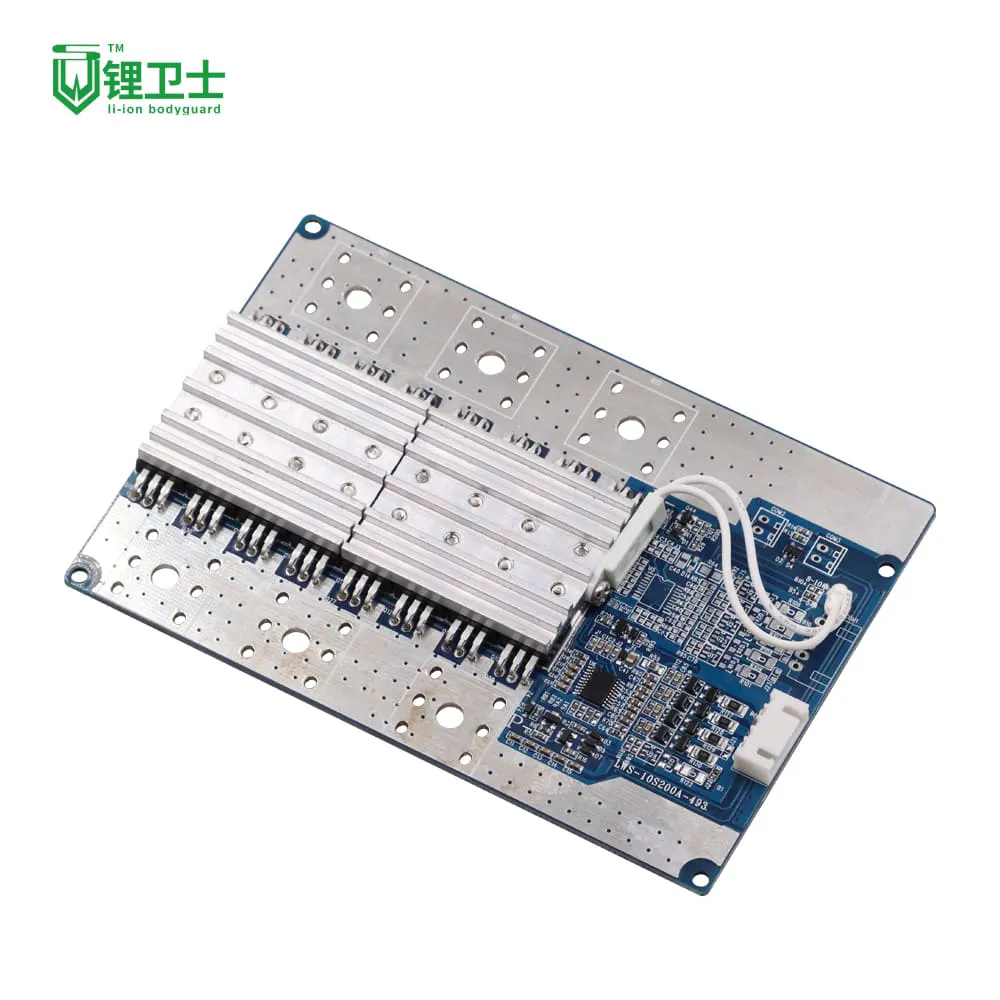

Printed Circuit Board (PCB): A PCB is a foundational component used to support and connect electronic components. In battery systems, PCBs are integral to the design and functioning of PCM and BMS, providing a physical platform for electrical connections and circuitry.

Key Features and Functions

1. Battery PCM

- Overcharge Protection: PCM prevents batteries from charging beyond their maximum voltage, which can lead to overheating or potential explosions.

- Over-Discharge Protection: It also safeguards against discharging the battery below a critical voltage, which can damage cells and reduce battery life.

- Short Circuit Protection: PCM detects and prevents short circuits, which can cause excessive current flow and potential damage or hazards.

- Temperature Monitoring: Many PCM units include temperature sensors to monitor and manage battery temperatures, further ensuring safety.

2. Battery Management System (BMS)

- Cell Balancing: BMS balances the charge across individual cells in a battery pack, ensuring even charging and discharging to enhance performance and longevity.

- State of Charge (SOC) and State of Health (SOH) Monitoring: BMS provides real-time data on the battery’s charge level and overall health, allowing for accurate performance assessments and maintenance.

- Thermal Management: It monitors and manages the battery’s temperature, ensuring it remains within safe operating ranges to prevent overheating.

- Communication: BMS communicates with external devices or systems, providing critical information on battery status and performance for integrated applications.

3. Printed Circuit Board (PCB)

- Support and Interconnection: PCB provides a stable platform to mount and interconnect electronic components, including those in PCM and BMS.

- Electrical Pathways: It creates precise electrical pathways for current to flow between components, ensuring efficient and reliable operation.

- Heat Dissipation: PCBs are designed to manage and dissipate heat generated by electronic components, helping to maintain optimal operating conditions.

Benefits of Battery PCM, BMS, and PCB

1. Enhanced Safety

- Protection Mechanisms: PCM and BMS provide critical protection against overcharging, over-discharging, and thermal issues, reducing the risk of battery-related accidents and prolonging battery life.

- Failure Prevention: By detecting and preventing potential failures, these systems enhance overall safety and reliability.

2. Improved Performance

- Optimized Charging and Discharging: PCM and BMS ensure that batteries are charged and discharged within safe and optimal ranges, improving performance and efficiency.

- Extended Battery Life: Proper management and protection reduce wear and tear on battery cells, extending the overall lifespan of the battery.

3. Increased Efficiency

- Cell Balancing: BMS ensures that all cells in a battery pack are charged and discharged evenly, maximizing efficiency and performance.

- Effective Heat Management: Efficient thermal management through PCBs and BMS helps maintain optimal operating conditions and prevent overheating.

4. Real-Time Monitoring and Control

- Data Insights: BMS provides real-time data on battery performance, allowing for better monitoring and control.

- Integration: Communication capabilities allow for integration with external systems, providing valuable insights and control for complex applications.

Applications of Battery PCM, BMS, and PCB

1. Electric Vehicles (EVs)

- Battery Packs: In EVs, PCM and BMS are essential for managing the performance and safety of large battery packs, ensuring efficient operation and longevity.

- Thermal Management: Effective thermal management is crucial for maintaining optimal battery temperatures and performance.

2. Renewable Energy Storage

- Solar and Wind Systems: PCM and BMS are used in battery storage systems for renewable energy, managing charge cycles and ensuring reliable energy storage and distribution.

- Grid Stability: They help in balancing energy storage and maintaining grid stability by providing real-time performance data.

3. Consumer Electronics

- Portable Devices: In consumer electronics such as smartphones and laptops, PCM and BMS manage battery performance, ensuring safe operation and extended battery life.

- Wearable Tech: Advanced BMS systems in wearables monitor battery health and performance, contributing to longer battery life and efficient usage.

4. Industrial Applications

- Backup Power Systems: Battery management systems are used in backup power systems for critical infrastructure, ensuring reliable power supply and efficient battery operation.

- Automated Equipment: PCM and BMS are integral to the operation of automated equipment, providing reliable power management and protection.

Choosing the Right Battery PCM, BMS, and PCB

1. Evaluate Battery Specifications

- Compatibility: Ensure that PCM, BMS, and PCB components are compatible with the specifications of the battery being used, including voltage, capacity, and cell configuration.

- Protection Features: Choose components that offer the necessary protection features for your application, such as overcharge protection or thermal management.

2. Consider Application Requirements

- Performance Needs: Select components that meet the performance requirements of your application, including monitoring accuracy and thermal management.

- Environmental Conditions: Consider environmental factors such as temperature, humidity, and potential exposure to chemicals when choosing components.

3. Review Manufacturer Specifications

- Quality and Reliability: Choose components from reputable manufacturers known for quality and reliability.

- Support and Service: Ensure that the manufacturer provides adequate support and service for their products, including technical assistance and warranty options.

Conclusion

Battery PCM, BMS, and PCB are integral components in ensuring the safe, efficient, and reliable operation of battery systems. By understanding their functions, benefits, and applications, you can make informed decisions that enhance battery performance and safety across a range of applications.

Embrace the advanced technology of battery protection and management systems to optimize your battery solutions, whether in electric vehicles, renewable energy storage, consumer electronics, or industrial applications. With the right components in place, you can ensure that your battery systems operate at their best, providing reliable power and extended lifespan.