Key components and considerations in rubber compound formulations

2024-04-30

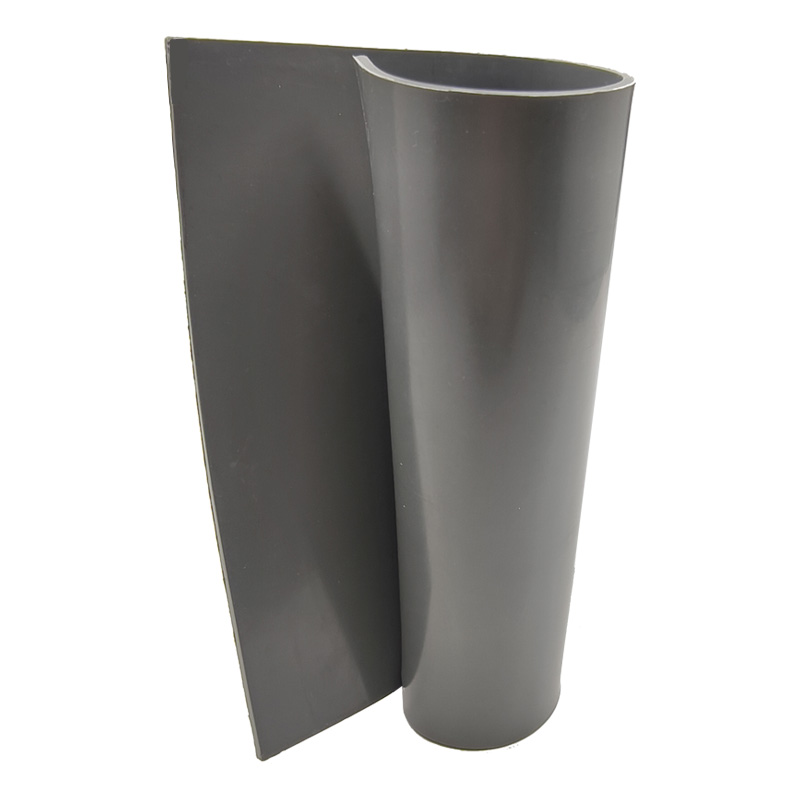

A rubber compound refers to a mixture of raw rubber materials and additives that are combined and processed to create a specific type of rubber with desired properties. Rubber compounds are used in various industries for manufacturing a wide range of products, including tires, seals, gaskets, hoses, conveyor belts, footwear, and many other rubber-based goods. Here are some key components and considerations in rubber compound formulations:

1. Base Polymers: The base polymer is the primary ingredient in a rubber compound and provides the fundamental properties of the finished rubber product. The most common base polymers used in rubber compounds include natural rubber (NR) and synthetic rubbers such as styrene-butadiene rubber (SBR), butadiene rubber (BR), nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), chloroprene rubber (CR), and silicone rubber (VMQ), among others. Each type of polymer offers unique characteristics such as elasticity, resilience, chemical resistance, and temperature stability.

2. Fillers: Fillers are added to rubber compounds to improve properties such as strength, durability, abrasion resistance, and stiffness. Common fillers include carbon black, silica, clay, calcium carbonate, and various mineral powders. Carbon black is one of the most widely used fillers due to its reinforcing properties, which enhance tensile strength and wear resistance.

3. Plasticizers: Plasticizers are additives used to soften rubber compounds and improve flexibility, elongation, and processability. They help reduce stiffness and improve the flow properties of the rubber during mixing and molding processes. Common plasticizers include oils, resins, and esters.

4. Vulcanizing Agents: Vulcanizing agents are chemicals used to cross-link the polymer chains in rubber compounds, transforming the soft, malleable material into a durable, elastic product. The most common vulcanizing agent is sulfur, which forms cross-links between polymer chains when heated in the presence of accelerators and activators.

5. Accelerators and Activators: Accelerators and activators are additives that promote the vulcanization process, reducing curing time and improving the efficiency of cross-linking reactions. Common accelerators include thiurams, sulfenamides, and thioureas, while activators such as zinc oxide and stearic acid enhance the activity of accelerators.

6. Antioxidants and Antiozonants: Antioxidants and antiozonants are additives used to protect rubber compounds from degradation caused by oxygen, ozone, heat, and UV radiation. These additives help extend the service life of rubber products by preventing cracking, hardening, and loss of mechanical properties over time.

7. Processing Aids: Processing aids are additives used to improve the processing characteristics of rubber compounds during mixing, milling, and molding operations. They help reduce viscosity, improve flowability, and enhance dispersion of ingredients. Common processing aids include lubricants, dispersing agents, and anti-tack agents.

8. Colorants and Pigments: Colorants and pigments are added to rubber compounds to impart desired colors or visual effects to finished products. They may include organic dyes, inorganic pigments, and color masterbatches.

Overall, the selection and formulation of rubber compounds involve careful consideration of ingredients and additives to achieve the desired balance of properties, performance, and cost-effectiveness for specific applications. Various testing and quality control measures are employed to ensure consistency and quality in rubber compound production.