Features associated with push button switches

2024-02-21

Push button switches come in various designs and configurations, offering different features to meet the specific requirements of diverse applications. Here are some common features associated with push button switches:

1. Momentary Operation: Many push button switches are designed for momentary operation, meaning they return to their original state when the actuating force is removed. This is suitable for applications where a temporary connection or disconnection is needed.

2. Latching Mechanism: Some push button switches have a latching mechanism that allows them to stay in their current state (either open or closed) until the button is pressed again. This is useful for applications that require a toggle-type switch.

3. Normally Open (NO) and Normally Closed (NC) Contacts: Push button switches can have one or both types of contacts. In normally open switches, the circuit is open when the button is not pressed, while in normally closed switches, the circuit is closed in the default state.

4. Illumination: Illuminated push button switches feature built-in LEDs or other light sources to provide visual feedback about the switch's status. This is particularly useful in low-light conditions or for indicating whether a device is on or off.

5. LED Color Options: In addition to illumination, some switches offer different LED color options, allowing for visual differentiation between various functions or statuses.

6. Tactile Feedback: Many push button switches provide tactile feedback, offering a distinct "click" or resistance when the button is pressed. This tactile response helps users confirm that the switch has been actuated.

7. Multiple Button Configurations: Some push button switches come with multiple buttons integrated into a single unit. This is common in control panels where different buttons serve distinct functions.

8. Environmental Sealing: Push button switches designed for harsh environments may feature sealing or encapsulation to protect against dust, moisture, or other environmental factors. This is essential for applications in industrial or outdoor settings.

9. Durability and Longevity: Quality push button switches are built to withstand repeated use without degradation in performance. Materials like metal or high-grade plastics are often used for enhanced durability.

10. Panel Mounting Options: Push button switches are designed for various mounting options, including panel mounting, PCB mounting, or integration into control systems, offering flexibility in installation.

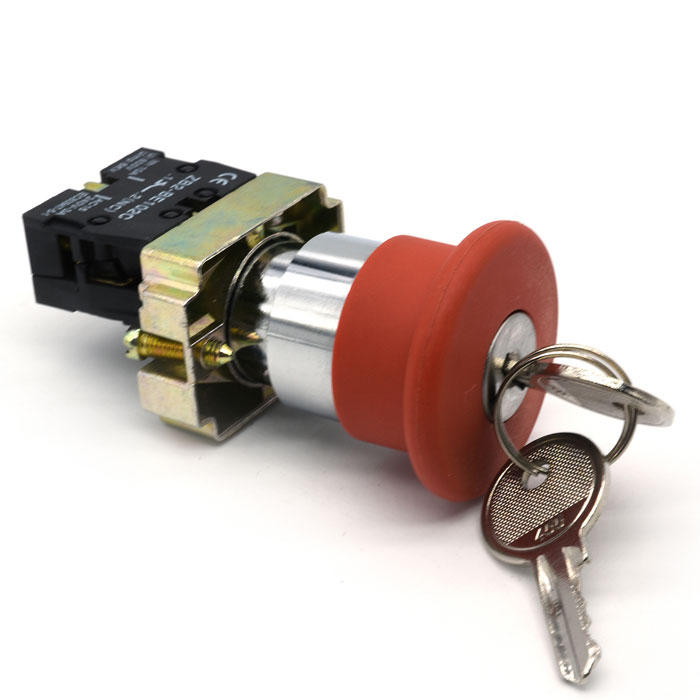

11. Mushroom-Head Emergency Stop: In industrial settings, emergency stop push button switches often have a distinctive mushroom-shaped head for easy identification and quick activation in emergency situations.

12. Variety of Sizes and Shapes: Push button switches come in various sizes and shapes to suit different applications. This includes miniature buttons for compact devices and larger buttons for industrial control panels.

13. Compliance with Standards: High-quality push button switches comply with industry standards for safety and performance, ensuring their reliability in diverse applications.

When selecting a push button switch, it's essential to consider the specific requirements of the application, including voltage and current ratings, environmental conditions, and the desired functionality to ensure the switch meets the intended purpose.