Exploring Stainless Steel Stamping Parts: Strength, Precision, and Versatility

2024-08-30

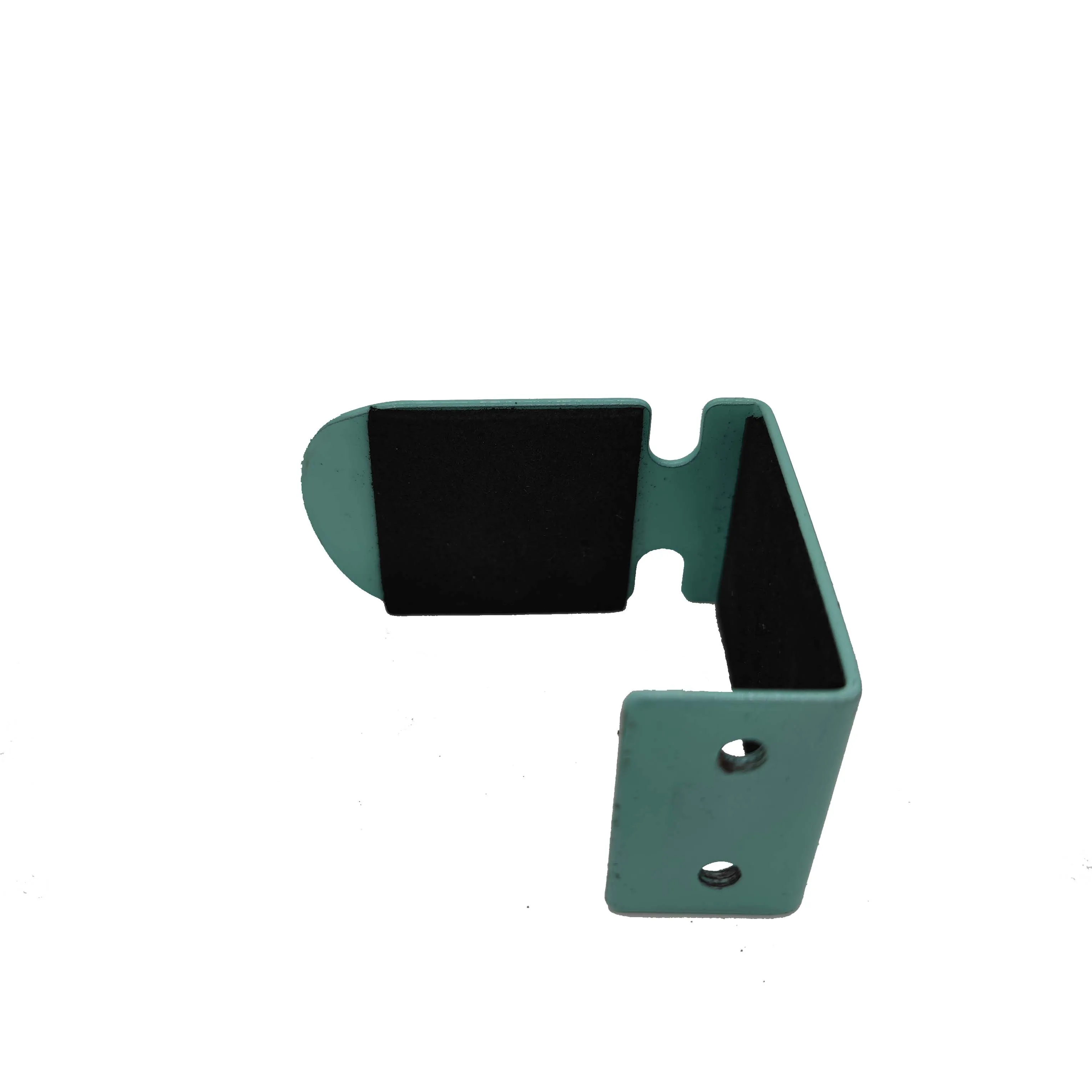

In the realm of manufacturing and engineering, stainless steel stamping parts are highly valued for their strength, durability, and precision. These components play a crucial role in various industries, from automotive and aerospace to electronics and consumer goods. This blog will delve into what stainless steel stamping parts are, their key features, benefits, and applications, and why they are an essential choice for many industrial and commercial projects.

What Are Stainless Steel Stamping Parts?

Stainless steel stamping parts are components produced through a stamping process using stainless steel as the base material. The stamping process involves placing a flat sheet of stainless steel into a die and using a press to shape it into specific forms. This method allows for the mass production of parts with high precision and consistent quality.

Key Features of Stainless Steel Stamping Parts

1. Material Composition:

- Stainless steel is an alloy of iron, chromium, and, in some cases, nickel and other elements. This composition gives stainless steel its corrosion resistance, strength, and aesthetic appeal.

2. Precision Manufacturing:

- The stamping process enables the production of parts with precise dimensions and intricate details. This precision is crucial for applications where exact measurements and fit are required.

3. Variety of Shapes:

- Stainless steel stamping can produce parts in a wide range of shapes and sizes, from simple flat pieces to complex geometries. This versatility makes it suitable for diverse applications.

4. High Strength:

- Stainless steel stamping parts are known for their high tensile strength and resistance to deformation. This strength is important for components that will endure significant stress or load.

5. Corrosion Resistance:

- Stainless steel’s inherent corrosion resistance makes it ideal for use in environments exposed to moisture, chemicals, or other corrosive elements. This property extends the lifespan of the parts.

6. Surface Finish:

- Stamping can achieve various surface finishes, including matte, polished, or textured. This flexibility allows for aesthetic customization and functional requirements.

Benefits of Stainless Steel Stamping Parts

1. Durability:

- Stainless steel stamping parts offer exceptional durability due to the robust nature of stainless steel. They withstand wear, impact, and harsh environmental conditions, making them ideal for demanding applications.

2. Corrosion Resistance:

- The corrosion-resistant properties of stainless steel ensure that the parts remain functional and visually appealing even when exposed to moisture, chemicals, or extreme temperatures.

3. Cost-Effectiveness:

- The stamping process allows for efficient mass production of parts, reducing manufacturing costs. Stainless steel’s durability also means lower maintenance and replacement costs over time.

4. Precision and Consistency:

- Stamping provides high precision and consistency in part production. Each part is manufactured to exact specifications, ensuring uniformity and reliable performance.

5. Customization:

- The stamping process can accommodate various designs and customizations, including complex shapes and specific dimensions. This flexibility meets the needs of diverse applications and industries.

6. Recyclability:

- Stainless steel is fully recyclable, contributing to sustainability and environmental responsibility. Used parts can be recycled and repurposed, reducing waste and resource consumption.

Applications of Stainless Steel Stamping Parts

1. Automotive Industry:

- Stainless steel stamping parts are used in automotive manufacturing for components such as brackets, clips, and panels. Their strength and corrosion resistance are crucial for parts exposed to harsh conditions.

2. Aerospace Industry:

- In aerospace, stainless steel stamping parts are utilized for structural components, fasteners, and engine parts. The high strength-to-weight ratio and resistance to extreme conditions are essential for aerospace applications.

3. Electronics:

- The electronics industry uses stainless steel stamping parts for housings, connectors, and heat sinks. Precision and durability are key for components that support electronic devices and systems.

4. Medical Devices:

- Stainless steel stamping parts are employed in medical devices and equipment due to their biocompatibility, strength, and resistance to sterilization processes. They are used in surgical instruments, implants, and diagnostic tools.

5. Consumer Goods:

- Household items and appliances often feature stainless steel stamping parts, including kitchen utensils, hardware, and decorative elements. The aesthetic appeal and durability of stainless steel enhance consumer products.

6. Construction:

- In the construction industry, stainless steel stamping parts are used for architectural elements, fasteners, and structural components. Their resistance to environmental factors makes them suitable for building applications.

Considerations for Stainless Steel Stamping Parts

1. Material Selection:

- Choose the appropriate grade of stainless steel based on the requirements of the application. Different grades offer varying levels of corrosion resistance, strength, and machinability.

2. Design and Tolerances:

- Work with experienced designers and engineers to ensure that the part design and tolerances are compatible with the stamping process. Proper design considerations ensure the part’s functionality and quality.

3. Quality Control:

- Implement rigorous quality control measures to verify the dimensions, surface finish, and performance of the stamped parts. Quality assurance is critical for maintaining consistency and reliability.

4. Cost Analysis:

- Perform a cost analysis to evaluate the benefits of stainless steel stamping compared to other manufacturing methods. Consider factors such as material costs, production volume, and long-term performance.

Conclusion

Stainless steel stamping parts are a cornerstone of modern manufacturing, offering a blend of strength, precision, and versatility. Their durable nature, corrosion resistance, and cost-effectiveness make them a preferred choice across various industries, from automotive and aerospace to medical devices and consumer goods. By understanding the features, benefits, and applications of stainless steel stamping parts, you can make informed decisions for your projects and ensure high-quality, reliable components. Whether you’re involved in product design, engineering, or procurement, stainless steel stamping parts provide a valuable solution for achieving excellence in manufacturing and performance.