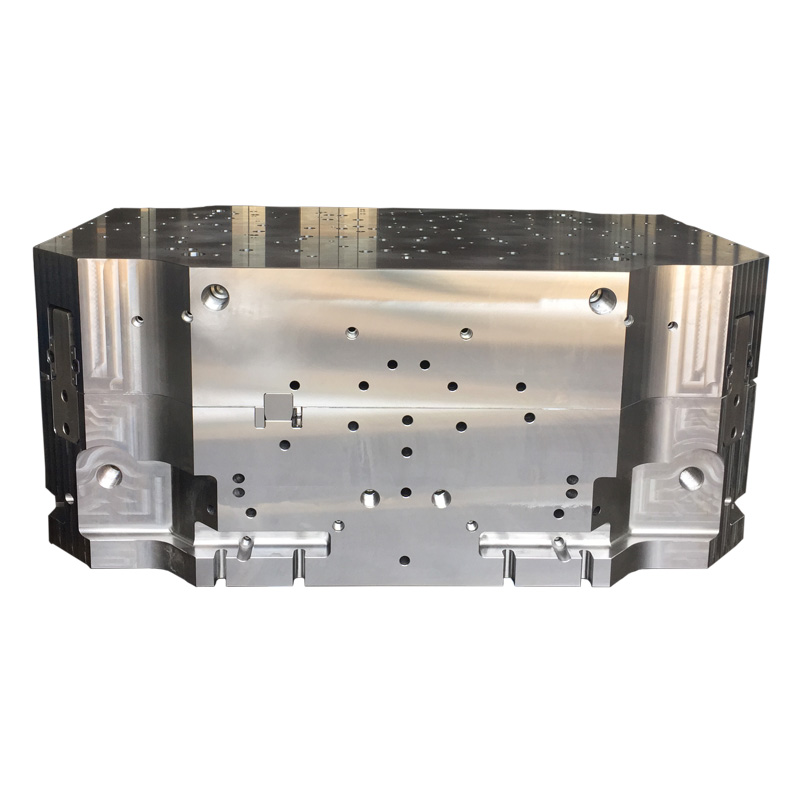

Components of Car Bumper Mold Base

2024-05-29

The mold base for a car bumper, typically referred to as a "mold base" or "tooling base," is a critical component in the injection molding process used to manufacture car bumpers. Here's an overview of the essential aspects of a car bumper mold base:

1. Material Selection

- Steel Alloys: Mold bases for car bumpers are commonly made from high-grade steel alloys, such as P20, H13, or 420 stainless steel, due to their excellent hardness, wear resistance, and machinability.

- Durability: The material needs to withstand high pressures and temperatures during the injection molding process, as well as resist wear and tear from repeated cycles.

2. Components of Mold Base

- Base Plate: The primary support structure that holds the mold cavity and core inserts.

- Support Pillars: These provide additional support and maintain alignment between the mold halves.

- Guide Pins and Bushings: Ensure precise alignment between the moving and stationary halves of the mold.

- Ejector System: Includes ejector pins, plates, and mechanisms to remove the molded bumper from the mold after cooling.

3. Design Considerations

- Cooling Channels: Integrated cooling channels help to regulate the temperature of the mold, reducing cycle times and ensuring uniform cooling of the bumper.

- Venting: Proper venting is essential to allow trapped air and gases to escape, preventing defects in the molded bumper.

- Parting Line: The location where the two halves of the mold meet. A well-designed parting line is crucial for minimizing flash (excess material) and ensuring a high-quality surface finish.

4. Manufacturing Process

- CNC Machining: Precision machining is used to create the intricate details of the mold cavity and core, ensuring the final bumper meets tight tolerances.

- Surface Treatment: Hardening and surface treatments, such as nitriding or chrome plating, can enhance the mold's durability and reduce wear.

- Polishing: The mold surfaces are polished to achieve the desired finish on the molded bumper, whether it be high-gloss or textured.

5. Maintenance and Longevity

- Regular Maintenance: Routine inspection and maintenance of the mold base are necessary to prolong its lifespan and ensure consistent production quality.

- Repair and Refurbishment: Over time, molds may require repair or refurbishment, such as re-polishing or replacing worn components, to maintain optimal performance.

6. Cost Considerations

- Initial Investment: The cost of a mold base for a car bumper is significant due to the precision engineering and high-quality materials involved.

- Production Volume: The investment in a high-quality mold base is justified by the large production volumes in the automotive industry, as it ensures consistent quality and reduces downtime.

7. Advances in Technology

- Simulation Software: Modern mold design often utilizes simulation software to optimize the design and predict potential issues, such as warping or cooling inefficiencies, before the mold is manufactured.

- Additive Manufacturing: In some cases, additive manufacturing techniques (3D printing) are used to create complex cooling channels or prototype molds, enhancing the overall performance and efficiency of the mold.

Conclusion

A car bumper mold base is a sophisticated and precisely engineered component essential for the mass production of automotive bumpers. Its design and construction involve careful material selection, advanced machining techniques, and thorough consideration of cooling, venting, and alignment. Proper maintenance and the integration of modern technologies can further enhance the mold's efficiency and longevity, ensuring high-quality bumper production.