Applications of EEK Films Nature

2024-05-29

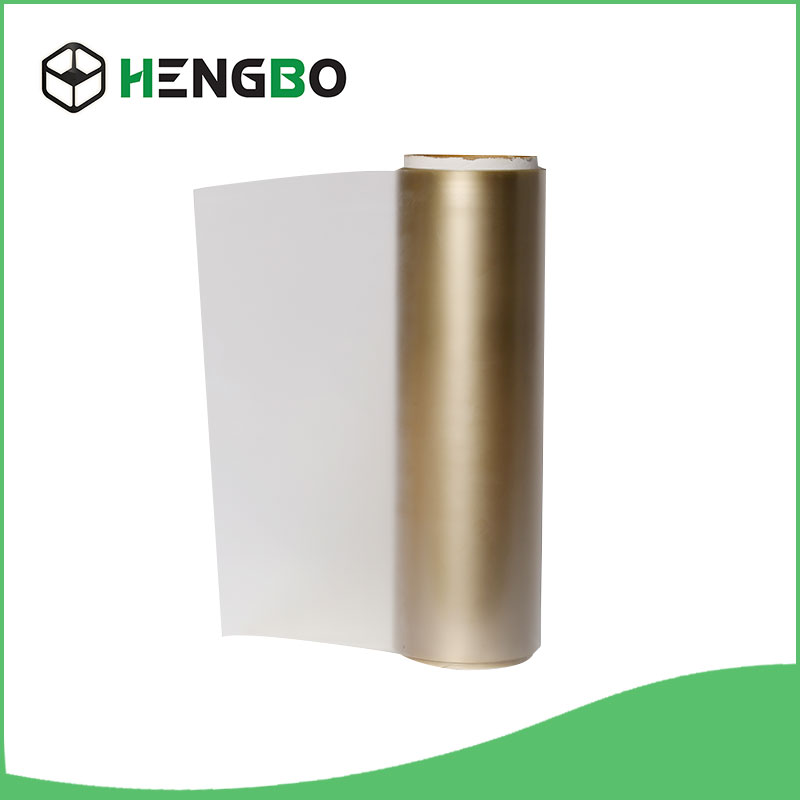

Polyether ether ketone (PEEK) is a high-performance engineering thermoplastic known for its excellent mechanical properties, chemical resistance, and thermal stability. PEEK films are used in a variety of applications across multiple industries due to their unique combination of properties. Here are some key aspects of the nature and characteristics of PEEK films:

1. Mechanical Properties

- Strength and Toughness: PEEK films possess high tensile strength and toughness, making them suitable for demanding applications where durability and resilience are critical.

- Wear and Abrasion Resistance: These films have excellent wear and abrasion resistance, which is essential for applications involving high friction and mechanical stress.

2. Thermal Properties

- High Temperature Resistance: PEEK films can withstand high temperatures without losing their mechanical properties. They have a melting point around 343°C (649°F) and can be used continuously at temperatures up to 250°C (482°F).

- Thermal Stability: PEEK maintains its properties over a wide temperature range, which makes it suitable for applications in harsh thermal environments.

3. Chemical Resistance

- Inertness: PEEK films are highly resistant to a wide range of chemicals, including acids, bases, and organic solvents. This chemical inertness makes them ideal for use in aggressive chemical environments.

- Hydrolysis Resistance: PEEK is resistant to hydrolysis, which means it does not degrade in the presence of water or steam. This property is particularly useful in medical and food processing applications.

4. Electrical Properties

- Insulation: PEEK films have excellent electrical insulating properties, making them suitable for use in electrical and electronic applications.

- Dielectric Stability: They exhibit stable dielectric properties over a broad range of frequencies and temperatures.

5. Dimensional Stability

- Low Creep and Shrinkage: PEEK films have low creep and shrinkage rates, which means they maintain their shape and dimensions under mechanical stress and thermal cycling.

- Precision: The dimensional stability of PEEK films is crucial for applications requiring precise and reliable performance over time.

6. Biocompatibility

- Medical Applications: PEEK is biocompatible and can be sterilized, making it suitable for medical implants and other healthcare applications. It does not cause adverse reactions when in contact with body tissues.

- FDA Approval: Many PEEK grades are FDA-approved for food contact and medical use.

7. Applications

- Aerospace and Automotive: Used in components that require high strength, thermal stability, and resistance to harsh environments.

- Electronics: Employed in insulation, connectors, and other electronic components due to its excellent electrical properties.

- Medical Devices: Utilized in implants, surgical instruments, and other medical devices because of its biocompatibility and sterilization capabilities.

- Industrial: Applied in various industrial settings for seals, bearings, and other components that require durability and chemical resistance.

Conclusion

PEEK films are highly valued in industries that demand superior performance materials. Their combination of mechanical strength, thermal stability, chemical resistance, and electrical properties makes them a versatile solution for many challenging applications.