The Unsung Hero of Heavy Machinery: The Carrier Roller

2023-10-18

Introduction

Heavy machinery is the backbone of many industries, from construction to mining and agriculture. These colossal machines rely on various components to function smoothly, and one often overlooked but crucial part is the carrier roller. In this blog, we'll shed light on the significance of the carrier roller, its role in heavy machinery, and why it's an unsung hero in the world of heavy equipment.

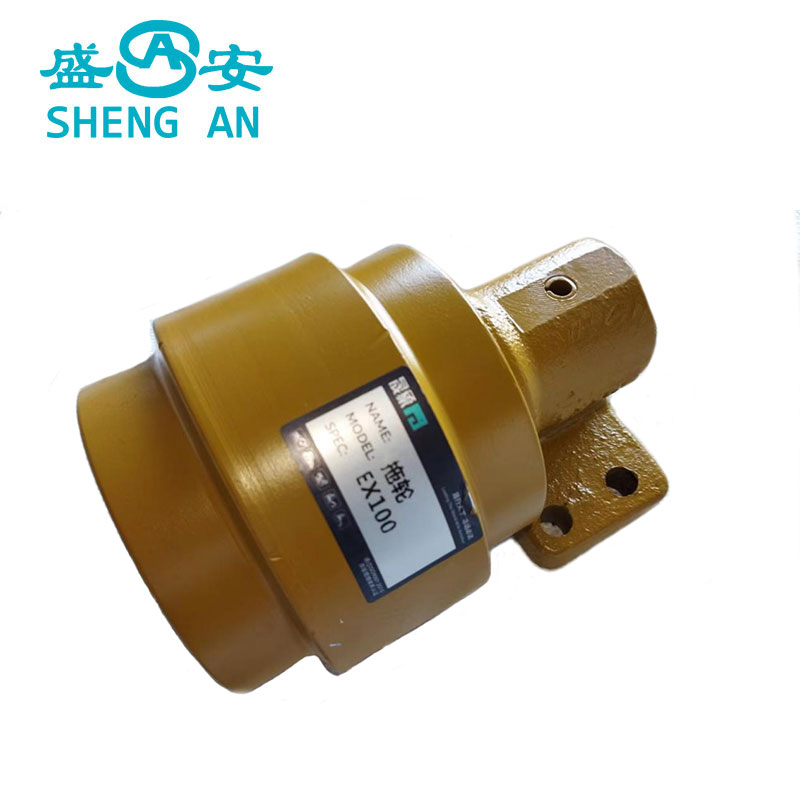

Understanding the Carrier Roller

The carrier roller is a critical component found in tracked heavy machinery, such as bulldozers, excavators, and crawler cranes. It's essentially a wheel or a set of wheels positioned on the undercarriage of the machine, and its primary function is to support and guide the track chain. The carrier roller plays several vital roles:

1. Load Distribution: Carrier rollers evenly distribute the weight of the machine, preventing excessive wear and tear on the track chain and ensuring stable and efficient operation.

2. Track Chain Tension: These rollers help maintain proper track tension, which is crucial for maintaining traction and stability while operating on uneven or challenging terrain.

3. Track Chain Guidance: Carrier rollers guide the track chain around the sprocket and idler, ensuring that it stays on track and functions smoothly during operation.

4. Reduced Friction: By rolling along the ground, carrier rollers reduce the friction between the track chain and the ground, leading to less wear and a longer lifespan for the tracks.

5. Shock Absorption: Carrier rollers also provide a degree of shock absorption, helping to cushion the impact when heavy machinery encounters obstacles or uneven surfaces.

Applications in Heavy Machinery

Carrier rollers are found in a wide range of heavy machinery, each tailored to specific industries and applications:

1. Construction: In construction machinery like bulldozers and excavators, carrier rollers are essential for stability, traction, and efficient operation on construction sites.

2. Mining: In the mining industry, where heavy machinery operates in extreme conditions, carrier rollers ensure that equipment can navigate rough terrain and extract valuable minerals.

3. Agriculture: Agricultural machinery, such as crawler tractors, relies on carrier rollers for traction and stability while plowing fields or performing other tasks on farms.

4. Forestry: In forestry equipment, carrier rollers help maneuver through dense forests and rough terrain while harvesting timber.

5. Infrastructure Development: Heavy machinery used in infrastructure development, including road construction and bridge building, depends on carrier rollers for durability and functionality.

Maintenance and Replacement

Given their critical role in heavy machinery, it's essential to perform regular maintenance on carrier rollers. This includes cleaning, lubricating, and inspecting for signs of wear and tear. If carrier rollers become damaged or worn beyond repair, they should be replaced promptly to avoid further damage to the machine and ensure safe and efficient operation.

Conclusion

While often overshadowed by more prominent components in heavy machinery, the carrier roller is undeniably an unsung hero. Its critical role in load distribution, track chain guidance, and overall equipment stability makes it an indispensable part of various industries. By supporting and guiding the track chain, carrier rollers enable heavy machinery to navigate challenging terrains, complete tasks efficiently, and contribute to the progress of numerous industries, making them a crucial cog in the wheel of progress.